Granite is a natural stone that is popular worldwide and is used in different applications from floors to kitchen counters. But, do you the journey of this popular natural stone? People love to use granite in their households and commercial uses, but still have no idea how is an Indian Granite reaches them. What is the path of journey through with Granite Pass? If you want to know, you need to stay here. When you understand this natural stone supply chain, it can help you source stones that are visually appealing, durable, and ethically extracted.

Table of Contents

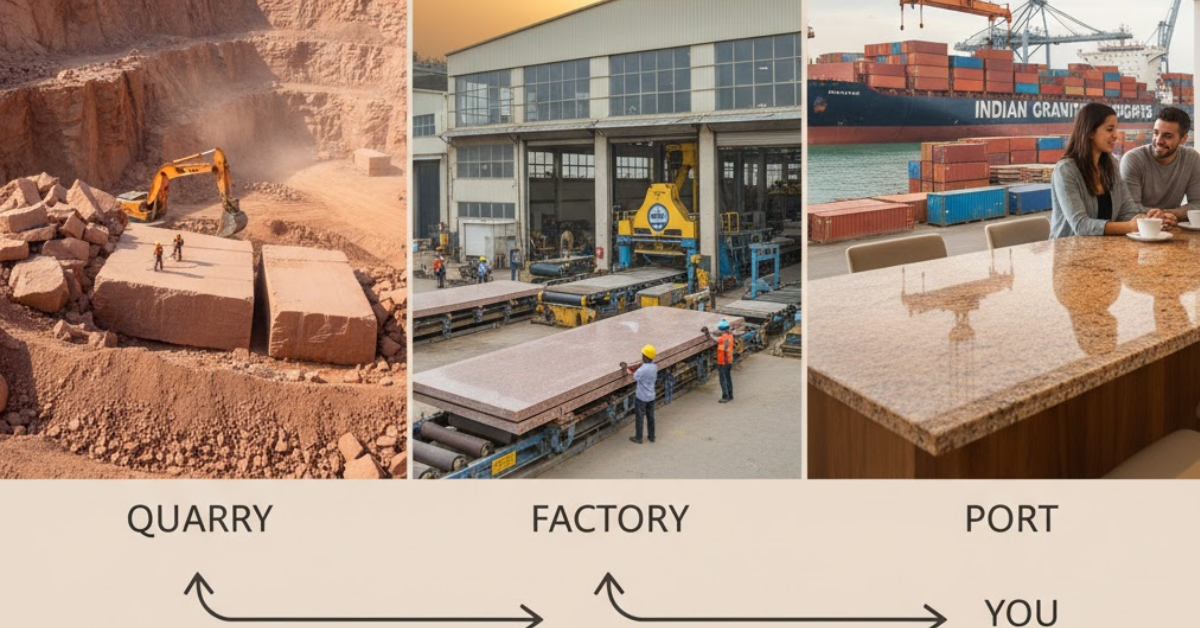

ToggleBelow is the journey of Indian Granite:

-

Granite Quarries in India

The first step of the journey is when granite is quarried in India. Journey begins in granite quarries in India, which are located in different states, including Karnataka, Andhra Pradesh, Rajasthan, and Tamil Nadu. These quarries extract blocks from the earth through different methods, such as drilling or cutting, emphasizing efficiency and safety.

- Granite Extraction Process

Granite extraction is meticulous procedure. Workers use diamond wire saws, chainsaws, or other modern equipment to detach large chunks of granite from the bedrock. The objective is to minimize waste and maintain the integrity of the stone. Ultimately, this is part of the assurance to maintain granite quality inspection standards later in the supply chain.

- Granite Processing Factory

After extraction, granite products are then transported to a granite processing factory. Here, qualified technicians apply advanced stone processing equipment to cut, shape, and finish the stone products. Rigor, precision, and care are critical components of the stone processing industry; even the smallest imperfection can interfere with the integrity of the stone product and the visual impressions made by the stone.

-

Granite Block Cutting

Once stones arrive at the factory, stones are cut into slabs via gang saws or wire saws. Granite block cutting offers a balance between timing and accuracy. The exact thickness and dimensions of a slab entirely depends on the client’s specifications and market demands for each product type, for example, a slab for a countertop, flooring, or cladding.

- Granite Polishing and Finishing

Post granite block cutting, slabs then move to a granite polishing and finishing bench. Polishing is used to expose and enhance the natural color or pattern in the stone. Then, finishing methods such as honed, brushed, or leathered give texture and versatility to the finished design. This is how and why a popular stone such as the Indian granite types of Black Galaxy, Kashmir White, or Absolute Black seem so beautiful.

- Granite Quality Inspection

Every slab of granite undergoes rigorous quality control inspections prior to shipping or sale. Quality control inspections ensure uniformity with thickness, colour, and cracks or defects. Quality control inspection ensures that clients and designers will have high-quality materials for their projects.

-

Granite Slab Packaging and Loading

Once approved, slabs are quality packed with protection to prevent damage while in transit. Granite slab packaging and loading requires the stones to be secured on crates and containers for domestic delivery and export. Handling slabs properly reduces waste and preserves the integrity of the stone.

- Granite Port Logistics

If you are an international client, granite port logistics are very important. A container is loaded onto a truck or train and once it arrives at the port the container will be stored in a structure until it is shipped. All of this must be coordinated accordingly for the timely arrival, which ensures the delivery of Indian granite in time for architects, builders, and designers.

-

Granite Exporters and Suppliers

Sourcing the right granite exporters and suppliers, like Nakul International, is key for premium projects. Reliable suppliers will ensure compliance with specifications, provide documentation for sustainability, and assist in a transparent manner throughout the natural stone supply chain. This transparency is very important in sourcing Indian granite for client projects.

Popular Indian Granite Types

India provides a beautiful array of granite types. Black Galaxy is popular for its dark, starry appearance; Kashmir White is known for its creamy elegance; and Absolute Black fits into sleek, modern interiors. There are significant characteristics that define each type that relate back to durability, maintenance, and design impact.

Sustainable Granite Quarrying Practices

Sustainable granite quarrying approaches are filling a void for the environmentally conscious clientele. Practices such as water recycling, controlled blasting, and land reclamation are ways to reduce environmental degradation during natural stone quarrying. When you demonstrate your pride as a supplier that you are collaborating with suppliers that are quarreling sustainably, you will elevate the beauty and responsibility of the effort.

Understanding the Natural Stone Supply Chain

The natural stone supply chain is complex, but interesting because from the quarry site to the manufacturer site and from the port to the project site, you must ensure quality from the extraction, process, inspect, package, and logistics stages. Attention to detail is required during each step to ensure quality. When buyers understand this hierarchy and what is involved, it allows for better transparency in order to make the best considerations for their project, as well as client satisfaction.

Final Thoughts

In conclusion, India has an elegant, strong, versatile granite supply sourced from quality quarries, making granite a preferred material for many countertops, flooring, and commercial projects. When considering granite towards the end-user of stone materials, what does the journey from quarry to project site look like?

If you need high-quality granite for your project, you need to consider manufacturers like Nakul International. Our clients are really happy with our high-quality and durable granite. Our team is committed to quarrying quality granite which is later shaped and finished with perfection.

Don’t miss out the opportunity to get the best quality Indian Granite at affordable prices at Nakul International!

Frequently Asked Questions for the Journey of Indian Granite

Question 1. How does granite from India go from the quarry to the slab?

Answer. Granite is extracted from quarries by wire saws, transported to the factory to be cut into slabs, polished, and quality inspected before packaging. Once properly processed, it has uniform appearance, durability, and aesthetics that are suitable for shipping domestically or internationally.

Question 2. What types of Indian granite are most popular?

Answer. Some of the more popular choices are the Black Galaxy, Kashmir White, and Absolute Black granites. Each offer unique color, pattern, and finish options for countertops, flooring, or wall cladding providing elegance and durability for residential and commercial projects.

Question 3. What kind of sustainable practices are followed in granite quarrying in India?

Answer. Sustainable practices in granite quarrying may involve water recycling, controlled extraction of blocks, minimal waste, and land reclamation. Suppliers that embrace sustainable practices step up to balance extraction with the aim of minimizing environmental harm, while also supporting responsible sourcing by its clients and projects.

Question 4. How does granite export work out of India?

Answer. After cutting, polishing, and inspection, slabs are packed, loaded into containers or a truck, and taken to the ports. Granite port logistics with a partner or specialized team to ensure safe handling and timely delivery to their international clients is the most effective way to ship granite while preserving quality and consistency.

Question 5. How can I find trustworthy granite exporters and suppliers in India?

Answer. It is best to seek suppliers that have certified quarries, adequate machinery that allows them to process stone to precision, transparent operations, and successful export experiences. A reliable supplier should also provide product specifications, samples if required, and logistics support as well.