Are you searching for high-quality quality precise stone for a large commercial space that enhances the appearance of large commercial spaces? We have a solution for every large-scale project that optimizes project timelines and reduces material wastage. Whether you are a builder, homeowner, or looking for the best house renovation option for European buildings. If you want to remove poorly calibrated machinery that leads to errors and material wastage, or maintain the quality of large-scale production for big projects. How Gangsaw Slab Thickness & Calibration Impact Large-Scale European Builds lets us understand.

If you want to know more about how gangsaw slab thickness & calibration impact large-scale European buildings, you are in the right place. In this article, we will explore the most critical factors and how to achieve flawless results for installation efficiency.

Table of Contents

ToggleDemand For The Gangsaw Slabs

According to the study of Grand View Research, the stone market is valued at USD 47.7 billion in 2022, and is expected to grow at a CAGR of 4.7% from 2023 to 2030. Or the granite segment is estimated to grow at a CAGR of 5.6% from 2023 to 2030.

Why Gangsaw Slab Thickness Matters for Large-Scale European Builds

Most of the large-scale European projects want to enhance their project’s luxurious aesthetic and overall project efficiency. Slab thickness makes a large impact on European buildings because ensuring the distribution and material wastage helps to improve high-quality aesthetics, and stands in European strict quality standards.

Inaccurate slab thickness impacts the structure and alignment of the project, and it leads to delays on commercial buildings and infrastructure projects that result in high losses.

Key Reasons For The Matter:

- Calibration impact or slab thickness ensures the longevity of the material.

- Proper alignment reduces the material wastage and manual errors.

- Save time or reduce the overall production costs

- Meets with European standards while boosting client satisfaction.

Understanding how the Gangsaw machines work helps to optimize the best resources and maximize client satisfaction, which enhances the goodwill of the industry.

What Is The Role Of Calibration In European Builds?

In European large-scale construction projects, it ensures every stone meets its precise quality standards and provides you with luxurious aesthetic looks for commercial or residential projects. When the calibrated gangsaw produces an uneven slab, it means compromising the structural integrity and spoiling the overall look of visual appeal or high-end custom countertops.

Efficient flawless surface finishing not only ensures you the durability and aesthetics it also ensures the natural stones ISO 9001. Every manufacturing standard helps to extend the lifespan, polish, equipment, and minimize the operational costs.

What Are The Key Benefits Of Proper Calibration?

- Ensure the slab accuracy by measuring dimensions and custom architectural designs.

- Maintain the slab consistency and accuracy with proper dimensional tolerance.

- Improve machine longevity by reducing blade wear and tear.

- Proper calibration stands in the European high-quality standards.

- Integrating with modern tools such as laser-guided systems for operational costs.

What Are The Impacts On Large-Scale European Projects?

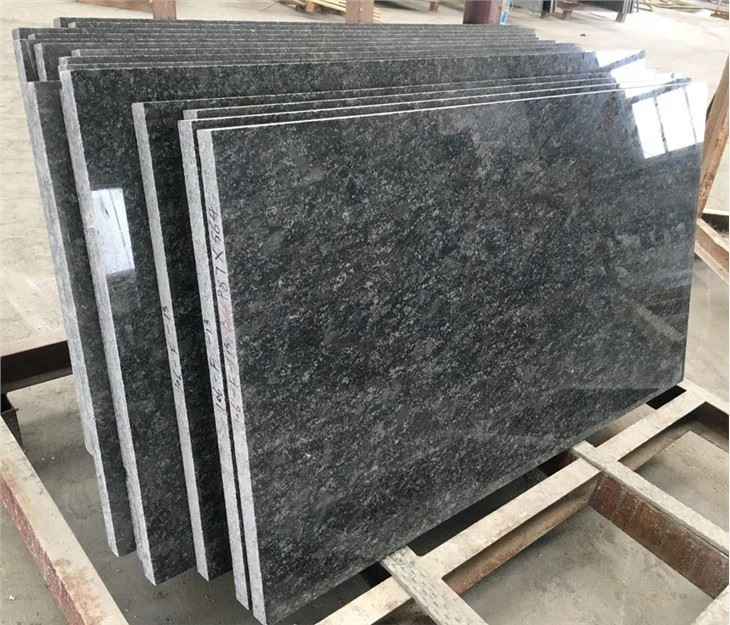

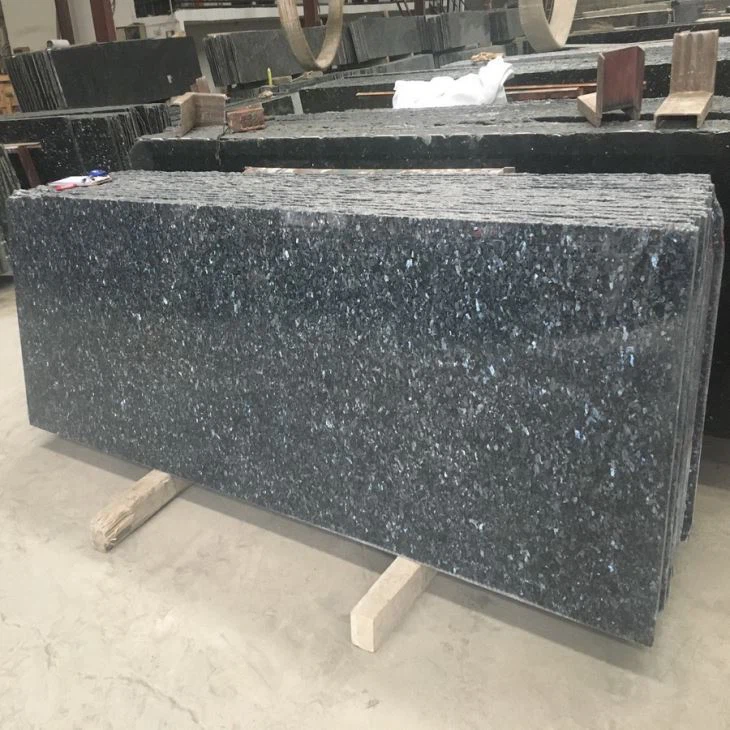

Every builder & contractor needs to measure slab thickness, gangsaw calibration, or go beyond the technical precision. It directly impacts the construction projects because the slab thickness or gangsaw slab adds aesthetic value and durable finishes in every commercial project. Most of the companies provide premium Italian marble or Granite Gangsaw Slab options for enhancing luxuriousness and long-term performance.

What Are The Key Applications Of European Buildings?

- High-rise official towers for granite durability & visual appeal

- Flawless stone finishes for premium outdoors.

- Consistent thickness helps you to handle energy, environment, or foot traffic.

Let’s discuss the best practices for optimizing slab performance.

For achieving superior slab performance in large-scale European buildings, every contractor wants to combine advanced technology with proper skilled craftsmanship or strict process control. Better gangway alignment & maintenance, ensuring accuracy, proper material optimization, and long-term durability. When you use high-quality stones, it helps to enhance the structural risks. And cost saving, reliable performance across the commercial or residential projects.

Best Practices:

- Needs to schedule regular gangsaw maintenance with proper calibration checks.

- Measure the slab thickness with advanced measurements.

- Always choose durable & premium marble granite because it does not show cracks and defects.

- Follow the proven technology with consistent dimensions.

Every large European building has the gangsaw machines working effectively with stone cutting, marble trends, granite slabs, with cutting accuracy or polishing equipment.

Why Choose Nakul International for Best Gangsaw Slab Thickness & Calibration Impact For Large-Scale Builds?

Nakul International is the most trusted and reputable manufacturer that delivers various types of natural stone products. This is an Indian based stone manufacturer that helps you to ensure the consistency, dimensions, and structural reliability for superior finishes. It builds its strong reputation like a concrete pillar in the market.

People Also Ask About How Gangsaw Slab Thickness & Calibration Impact Large-Scale European Builds.

Q.1 What is the gangsawslab thickness or calibration impact?

A: It means ensuring the slab thickness without affecting the stone quality or less material wastage.

Q.2 Is The Gang Saw Slab Stone A Cost-Effective Solution For A Residential Apartment?

A: Gangsaw slabs come with uniform thickness, less material waste, and a durable quality.

Q.3 Why do large projects prefer gangsaw slabs?

A: It works long-lasting because of consistent quality, slab thickness, and less material waste.

Q.4 Does calibration require less maintenance?

A: Proper slab thickness & calibration reduce the installation errors and long-term maintenance needs.