Slate Manufacturer & Exporter From India

Showing all 16 results

-

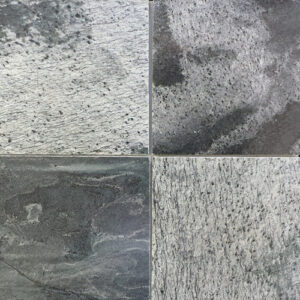

Black Slate

-

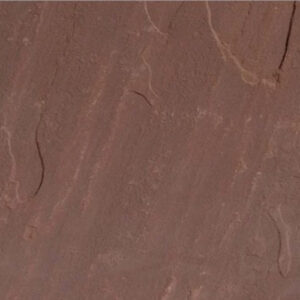

Chocolate Slate

-

Copper Slate

-

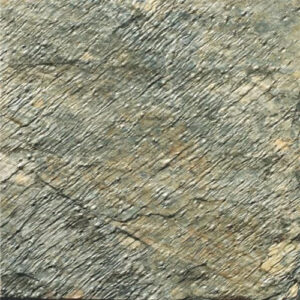

Deoli Green Slate

-

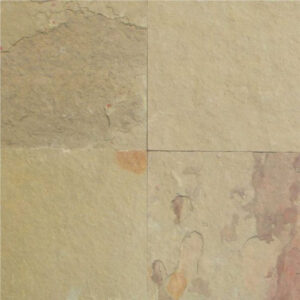

Golden Slate

-

Indian Autumn Slate

-

Indian Multicolor Slate

-

Multi Pink Slate

-

Ocean Green Slate

-

Premium Black Slate

-

Pure Pink Slate

-

Red Slate

-

Rosa Slate

-

Silver Grey Slate

-

Silver Shine Slate

-

Yellow Multi Slate

Slate Manufacturer in India – A slate is a metamorphic rock made of clay or volcanic ash found in mountains or volcanic arcs. Slates are finely-grained rocks and are used for construction. Slates have a lot of use in commercial and residential interiors. If you are looking for a Slate Manufacturer, suppliers & exporters, we are one of the best options for you. Below you know the reason so stay connected with us.

Slate manufacturing is a process of mining and extracting stones such as marble, and granite with the help of heavy and advanced machinery. Slates are extracted from a slate query or slate mine. The process of turning a rock into slate after exposing it to constant heat and pressure is complex thus only experienced are allowed to do its mining and extracting.

Everything you need to know about Slate Manufacturing –

This process requires the extraction or mining of slate stones to process them and give finishing to the final product.

Extraction: Slate is acquired through slate quarries or slate mines. There are various methods used to mine them such as cutting, chiseling or blasting. These are quarried or mined from slate beds or pits. Many large racks are extracted easily compared to small ones.

Rough Cutting: These extracted pieces of slate are then cut with the help of saws or splitters. This is a small yet important part to split them into small sizes for use.

Trimming and Shaping: Then the slate pieces are crushed into desirable shapes and designs. Trimming the edges for a smooth texture is necessary.

Splitting: Then the slates are further split to make slate sheets. Manual machines and technical tools are used to ensure uniform thickness and proper size of slate.

Finishing: Then the slate is given a finishing touch. The desired design or appearance of the slate is finished, polishing, & brushed to smoothen the surface.

Quality control: Then the quality, hardness, thickness, size, colour, design, texture, and durability of the slate sheet are checked.

Packing and export: Lastly, the slate is packed carefully for use and exported where it is demanded.

Here is the List of Top Selling Slate Stone –

- Cooper slate

- Yellow multi slate

- Silver Shine slate

- Red slate

- Black slate

- Golden slate

- Indian autumn slate

- Indian multicolor slate

- Pure pink slate

- Ocean green slate

- Premium black slate

- Silver Grey sate

- Rosa slate

- Mutipink slate

- Chocolate slate

- Deoli Green Slate

Let’s know the types of Slate that we Export –

The slate is formed by combining minerals sometimes and it is done so to produce new textures, design, hardness and quality. Many minerals used in slate manufacture are:

Roofing Slate: It is used for covering roofs in houses, industry, buildings, etc. Its hardness is balanced and thus its life expectancy is over a hundred years. It needs to be properly maintained. After it is installed, it gives a casual yet sophisticated look. Roof slates are made to be non-combustible to protect from heat and fire. Its quality remains the same in harsh weather conditions.

Flooring slate: Used for flooring walkways, kitchens, hospitals, bathrooms, etc. These are durable and their hardness helps them prevent cracks, defects, and scratches. Made from great quality material to reduce slipperiness so people don’t slip while walking on them. It makes the floor appear aesthetic. The floor slates come in a wide range of colours, designs, and textures. Great for both indoor and outdoor flooring and it has thermal prevention.

Wall Cladding Slate: These slates are used to enhance the outlook of walls. They make any wall look natural and beautiful. It protects the walls for a long time and needs very little maintenance. It lets heat dispatch and hence prevents fire hazards.

Some other types are countertop slate, landscape slate, slate pavers, slate chippings, stepping slate stones, etc.

Here are some reasons why you should choose Slate –

- Prevents damage, and cracks, and is resistant to heat.

- It gives an everlasting look that comes in various textures and colours.

- They require less maintenance and are easy to clean.

- They are eco-friendly and do not harm nature.

- Also, It is Durable.

Here are you know where you should use slates –

- Perfect for kitchen flooring as it is fire resistant.

- It makes the wall appear fantastic and protects the interior.

- It is used for making pathways and decorative items.

- Used for making bathroom and kitchen facilities.

- It helps in elevating the landscape and gives gardens a classic appeal.

- Also, It is used in roofing.

Why are we the best choice for Slate Manufacturers in India?

Nakul International was founded 25 years ago by Mr. Jitendar Agarwal in Mayosore, Karnatka. In 1999, the newly formed Nakul International aimed to be the best in exporting, supplying and manufacturing of granite & marble. We have a team of excellent workforce who have a lot of expertise in this field.

Our team also engages in export products in many countries such as the USA, UK, Armenia, Georgia, Serbia, etc. All our products are top-notch quality and we have maintained the integrity of our products since we started the company.

List of perks: Why you should join us

- Customized and designed slates

- Available for you 24*7.

- 100% satisfaction to our clients.

- Advanced technology and machinery to extract and polish our slates.

- Our slates are in high demand globally used for both residential and commercial use.

- Texture and design are incredible and the color range is limitless.

- Provide bulk orders thus easily accessible.

- Look attractive as our artisans provide the best facilities.

- State-of-the-art manufacturing with talented minds.

How to contact us?

Name:- Nakul International.

Address:- Plot No.11/B, Kellamballi Industrial Area, Badanaguppe, Chamrajanagar – 571313 Karnataka, India.

Mail:- info@nakulinternational.com

Phone number:- +91 9731143244, +91 8618284386

FAQs Related To Slate Manufacturers in India:

Q1. Where in India is Slate found?

Ans. Slate is found in deposits of Himachal Pradesh’s Chamba, Kangra, Kullu, Mandi, Shimla, etc. in India. In India, slate is also found in the Aravali range in Haryana and Rajasthan. In South India, slates are found in Tamil Nadu and Andhra Pradesh.

Q2. What are the qualities that make slate a sought-after commodity?

Ans. Slates are durable, natural, recyclable, beautiful, used in a lot of places and have thermal properties.

Q3. What is the process of slate manufacturing?

Ans. Slate manufacturing is a process of extracting, cutting, trimming, and finishing a slate sheet while maintaining its extensive quality.

Q4. Is there any harm to nature by slates?

Ans. No, as slates are sustainable and eco-friendly no harm is caused to nature.

Popular Searches for Slate Manufacturer & Exporter From India –

Best slate manufacturer & exporter from India | Slate manufacturer in India | slate exporters from India | Slate Products list | Best Slate suppliers in India